Products

Injection Molded Plastic Components

Our plastic injection molding facilities boast state-of-the-art technology, enabling precision and efficiency in every step of the manufacturing process. From initial design to final production, our streamlined facilities ensure seamless operation and consistent quality. Utilizing high-grade materials such as TPU, PA6abd 66 , POM , PP, PHDPE and ABS, we cater to a wide range of industry needs. Our expertise in plastic injection molding allows us to produce intricate components with utmost precision, meeting the most stringent specifications.

With a focus on sustainability, our facilities are equipped to optimize material usage and minimize waste, contributing to a greener future. From concept to completion, trust our plastic injection molding facilities to deliver superior results efficiently and reliably.

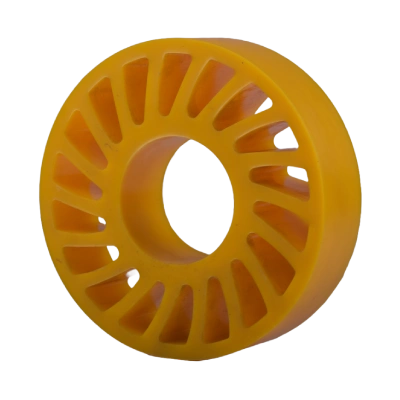

Polyurethane Components

Ally International is bestowed with an experienced team of professionals, we manufacture and supply an extensive range of cast polyurethane Products. Our products offer versatile applications and specialized features tailored to various industries. From durable industrial components to resilient Hopper liners and flexible seals, our polyurethane solutions excel in demanding environments. With exceptional abrasion resistance, impact absorption, and chemical resilience, our products are ideal for industries ranging from automotive and construction to mining and manufacturing. Whether it’s custom-molded parts or high-performance lining , our CAST polyurethane products deliver unmatched durability and performance.

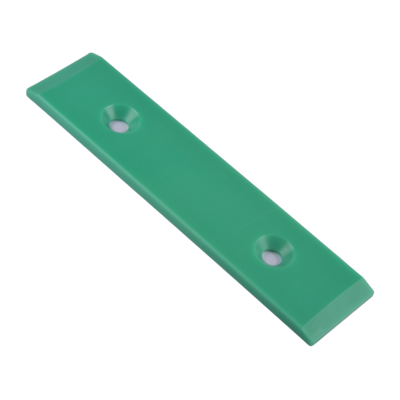

UHMWPE Products

UHMWPE (Ultra-High Molecular Weight Polyethylene) products are widely utilized across various industries for their exceptional properties and versatility. In material handling and conveying, UHMWPE components such as conveyor change parts , rollers, and guides offer superior abrasion resistance, low friction, and durability, ensuring smooth and efficient operations.

In the food industry, UHMWPE is utilized for food-grade conveyors, cutting boards, and packaging components due to its non-toxicity, resistance to chemicals, and ease of cleaning, maintaining hygiene standards. For the paper industry, UHMWPE is used in paper machine parts such as suction box covers, doctor blades, and wear strips, providing excellent wear resistance and reducing downtime. In the automotive sector, UHMWPE finds application in various components including bushings, gears, and sliders due to its self-lubricating properties, noise reduction, and resistance to impact and chemicals, enhancing performance and longevity.

In general engineering, UHMWPE is employed in a wide range of applications such as bearings, gears, seals, and wear plates, offering exceptional wear resistance, low coefficient of friction, and high impact strength, contributing to improved efficiency and reliability. The specialty of UHMWPE lies in its ability to perform under demanding conditions, providing superior wear resistance, low friction, corrosion resistance, and impact strength across diverse applications, making it an ideal choice for industries requiring high-performance materials.

Polyamide Components

Nylon and MC nylon (Nylon with Molybdenum Disulfide) products offer a wide range of applications and specialized features to meet diverse industrial needs. In material handling and conveying, Nylon and MC nylon components such as gears, rollers, and bushings provide excellent wear resistance, low friction, and self-lubricating properties, ensuring smooth and efficient operations. In the automotive industry, Nylon and MC nylon find application in various parts including bearings, gears, and timing belts due to their high strength, impact resistance, and ability to withstand harsh operating conditions, enhancing performance and reliability.

For machinery and equipment manufacturing, Nylon and MC nylon are utilized in gears, bearings, and wear plates, offering exceptional wear resistance, low coefficient of friction, and resistance to chemicals and corrosion, contributing to longer service life and reduced maintenance. In the marine industry, Nylon and MC nylon are used in components such as propeller shaft bearings, bushings, and pulleys due to their resistance to saltwater corrosion and excellent load-bearing capabilities, ensuring reliable performance in marine environments. The specialty of Nylon and MC nylon lies in their ability to perform under demanding conditions, providing superior mechanical properties, chemical resistance, and dimensional stability, making them suitable for a wide range of applications across industries.

PTFE Components

PTFE (Polytetrafluoroethylene) products have a diverse range of applications and unique performance characteristics that make them highly sought after in various industries. In the automotive sector, PTFE is utilized in gaskets, seals, and bearings due to its excellent chemical resistance, high temperature stability, and low friction properties, ensuring reliable performance in harsh environments. In the aerospace industry, PTFE finds application in aircraft components such as seals, O-rings, and electrical insulation due to its lightweight nature, resistance to extreme temperatures, and non-stick properties, contributing to enhanced safety and performance.

In the food and beverage industry, PTFE coatings are applied to cookware, bakeware, and conveyor belts due to their non-stick properties, chemical inertness, and resistance to high temperatures, ensuring food safety and ease of cleaning. In industrial applications, PTFE is used in bearings, seals, and pump components due to its exceptional chemical resistance, low coefficient of friction, and resistance to wear, reducing maintenance requirements and prolonging equipment life. The specialty of PTFE lies in its unique combination of properties, including high chemical resistance, low friction, non-stick surface, and high temperature stability, making it suitable for a wide range of applications where reliability and performance are paramount.

Polypropylene Products

Our polypropylene products are crafted with precision using high-quality thermoplastic polymer resin, known for its exceptional versatility and durability. Designed to meet the demands of diverse applications, these products are widely utilized across automotive, packaging, and industrial sectors.

With excellent chemical resistance, lightweight construction, and temperature stability, polypropylene sheets and rods provide reliable performance in challenging environments. Manufactured with sustainability in mind, our polypropylene solutions are recyclable and engineered to deliver efficiency and longevity, making them an ideal choice for modern industrial needs.

Acetal Products

Our Acetal products, crafted using premium-grade polyoxymethylene (POM) resin, are renowned for their exceptional dimensional stability, high tensile strength, and low moisture absorption. With properties like excellent machinability, rigidity, and durability, these thermoplastic solutions are ideal for precision engineering applications across industries.

Acetal sheets and rods provide outstanding strength and stiffness, ensuring reliable performance in demanding environments. Designed with versatility and efficiency in mind, our Acetal products meet the highest industry standards, making them the perfect choice for injection molding and other advanced manufacturing needs.

Nylon Products

Our Nylon products, crafted from premium-grade polyamide (PA), deliver unmatched strength, durability, and versatility. Known for their high temperature and chemical resistance, Nylon 6 and Nylon 66 provide exceptional mechanical properties, making them ideal for demanding industrial applications.

From Nylon rods and gears to specialized components like bushes, our products serve industries including food processing, construction, agriculture, mining, and more. Lightweight yet strong, Nylon is an excellent alternative to rubber, latex, and metal, offering cost-effective and efficient solutions for modern manufacturing needs. Designed for reliability and performance, our Nylon products set the standard for excellence.

Peek Products

Our PEEK products, crafted from high-performance polymer, provide an exceptional alternative to metal components in demanding applications. Renowned for their toughness, rigidity, and superior creep resistance, PEEK materials are ideal for high-tolerance, high-heat, and chemical-resistant environments.

PEEK rods or PEEK gears, these products offer outstanding mechanical properties and wear resistance, making them perfect for manufacturing stronger, lighter components that perform reliably in harsh conditions. Designed for easy handling and unmatched strength, PEEK products meet the highest standards for industrial and engineering excellence.

Fiberglass Products

Our Fiberglass products, including high-quality Fiberglass Rods, are crafted from premium composite materials to meet diverse industrial needs. Known for their extraordinary robustness, lightweight design, and excellent chemical resistance, these products are perfect for demanding applications. With superior strength and durability, Fiberglass Rods are widely used in constructing scaffolding for commercial construction projects and other industrial purposes. Designed to deliver reliability and performance, our Fiberglass products offer a versatile solution for modern engineering and construction challenges.